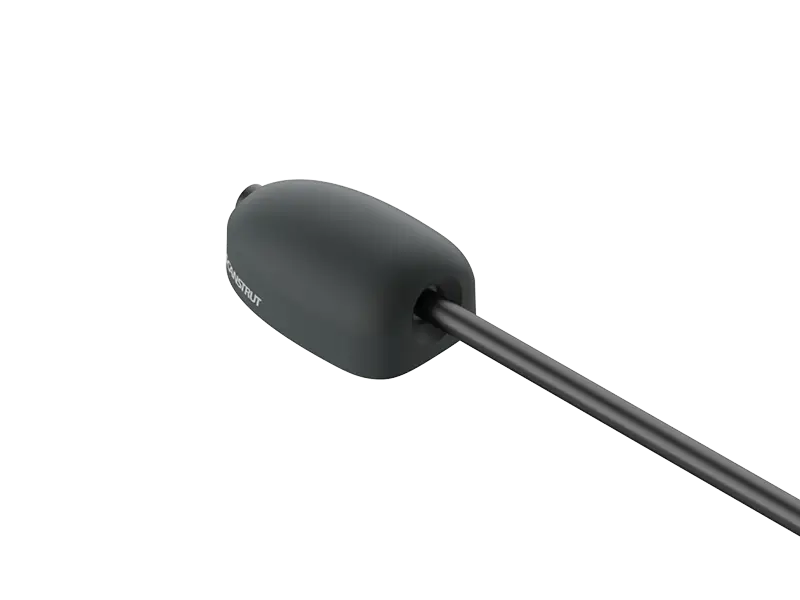

Horizontal Cable Seal

DS-H6

Our most compact horizontal entry cable seal, is designed for cables from 2-6mm (0.08"-0.24").

Featuring an aesthetic dome-shaped profile to provide a stronger, impact-resistant design and captive nuts in the base for an easy assembly.

Our most compact horizontal entry cable seal, is designed for cables from 2-6mm (0.08"-0.24"). Perfect for installing on solar panels, light bars, lights and other rooftop electronics.

Design

Featuring an aesthetic dome-shaped profile to provide a stronger, impact-resistant design and captive nuts in the base for easy assembly.

Marine Grade Plastics

Made from marine-grade plastic, selected for its UV-stable and hard-wearing properties. Giving that peace of mind for long-lasting performance.

Easy Installation

To speed up installation time, the cable seals are made with captive nuts, making the installation as simple and fast as possible.

Key Features

- Easy fit cable routing that cuts down your installation time

- A guaranteed 100% watertight seal

- Designed for a range of cable diameters

- Perfect for solar panels, light bars, lights and other rooftop electronics

- The low-profile construction is impact resistant and provides extra protection from water

- Captive nuts make for easy assembly and also allow for reliable repeat installations

- No messy sealant on bungs

Technical Specification

| Material | High Impact Plastic |

| Height | 20mm (0.79”) |

| Length | 46mm (1.81”) |

| Colour | Grey |

| Cable Diameter | 2-6mm (0.08-0.24") |

| Bungs | 1 x 2mm (0.08") / 1x 3mm (0.12") / 1 x 4mm (0.16") / 1 x 5mm (0.20") / 1 x 6mm (0.24") |

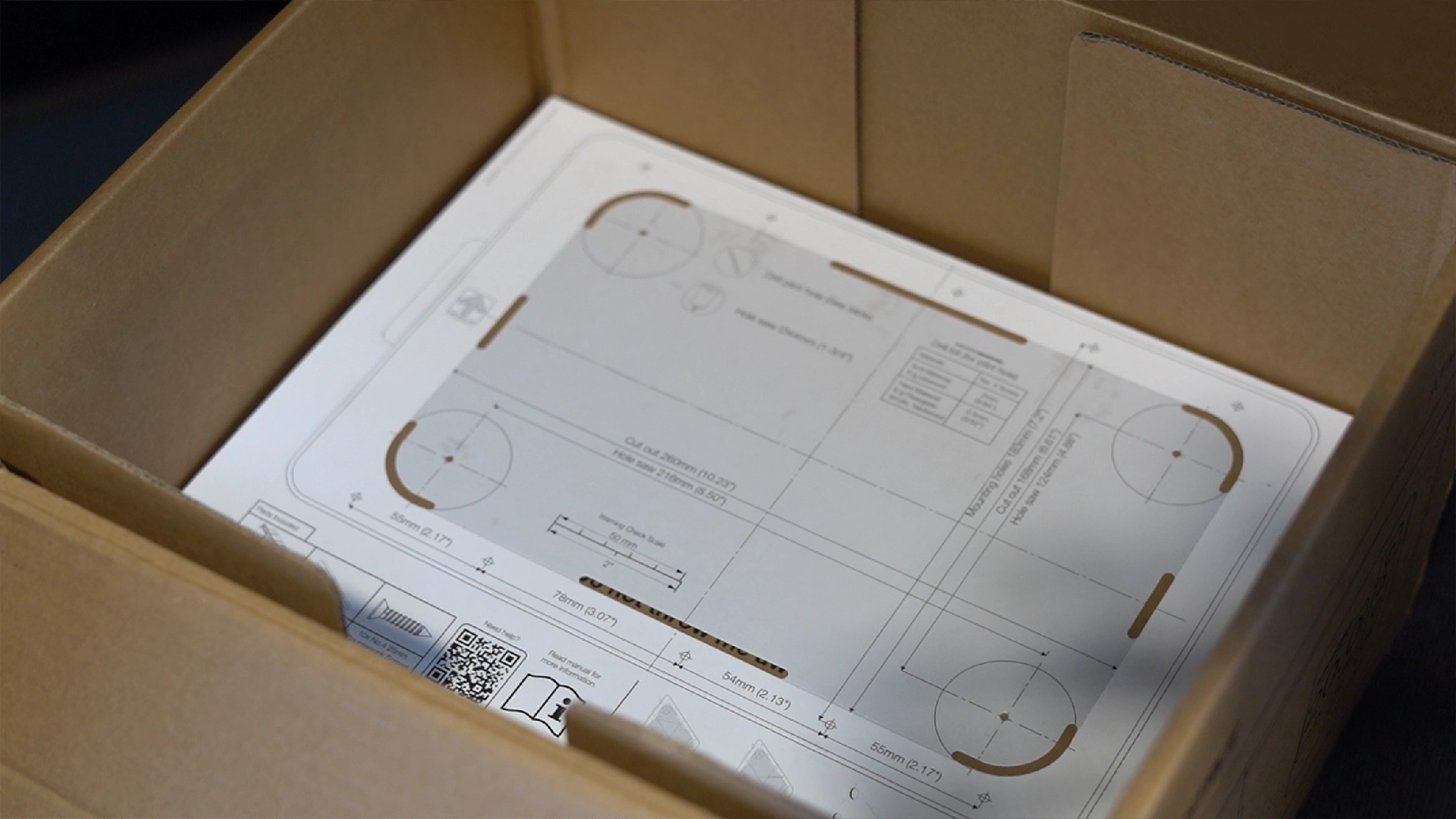

Installation Guide

The testing standard at Scanstrut is encapsulated by the acronym SCA, which stands for Safe, Certified, and Approved. With over 35 years of experience and expertise in designing products for outdoor use, Scanstrut design products to be able to thrive in the harshest of outdoor environments.

Before any product is released, it must pass through the rigorous testing program which involves assessments in electrical, mechanical, U.V., corrosion, thermal, and waterproof categories. To ensure the highest level of accuracy, testing is conducted both internally and by independent ISO accredited test houses.

This commitment to quality has earned Scanstrut the approval of renowned names such as Mercury Marine, Grady White Boats, Boston Whaler, Winnebago, Airstream and many more. To learn more about the SCA testing program and certifications, get in touch.

Corrosion Test

100-hours of a special formula salt spray that simulates accelerated marine environmental effects on the product.

FEA Analysis

Finite Element Analysis, simulates the behaviour of the design in virtual conditions to allow us to optimise the design before prototyping and physical testing.

Material Test

Positive Material Identification (PMI) ensures consistent quality of 316 Stainless Steel and Aluminium products. This controls strength and environmental performance.

Accelerated UV Material Test

We accelerate the effects of UV exposure to replicate our products usage in extreme tropical climates. We do this to ensure parts do not become brittle, discolour or fail over time.

PROP65

Confirms the exclusion of substances of very high concern in our products, with the aim of protecting human and animal health.

IP Test

Water and dust protection under test laboratory conditions to international IP standards. We test between IPX4 (waterjet) and IP68 (submersion).Related Products

DS-H6-BLK

Horizontal Cable Seal

DS-H10-BLK

Horizontal Cable Seal

DS-HD6-BLK

Double Horizontal Cable Seal

DS-HD10-BLK

Double Horizontal Cable Seal

DS-H10

Horizontal Cable Seal

DS-HD6

Double Horizontal Cable Seal

DS-HD10

Double Horizontal Cable Seal

3 mins

3 mins How to Install A Scanstrut Starlink...

For the best-fitting, purposely designed, and engineered option, here is our tried and tested... Read more

3 mins

3 mins The Top Van Design Considerations...

3 mins

3 mins Key Trends Shaping 2025

2025 has brought together several key trends across industries,... Read more

3 mins

3 mins In conversation with Teulu Tribe

We catch-up with TeuluTribe, aka, Becka and Zach, to hear their intro to sailing and... Read more

7 mins

7 mins In conversation with Viggo Boats

In this interview we speak with Douglas Matton, Production & Brand Manager at

3 mins

3 mins The ultimate Vanlife Game-Changer

3 mins

3 mins 4 trends we saw at boot Düsseldorf

3 mins

3 mins How we reduced our plastic packaging

Design

Innovation

Partner

Sustainable

Quality