Starlink

Are you ready to take your Starlink experience to the next level?

Look no further than Scanstrut, the industry leader in innovative and reliable marine mounting solutions. Scanstrut Starlink Mounts are engineered to optimize your Starlink performance, ensuring you get the best possible internet connectivity, no matter where you are out on the water.

- Designed to fit Starlink Flat High-Performance.

- Pre-drilled mounting holes allow the hardware to fasten directly to the wedge.

- Built-in Scanstrut Cable Seal ensures a watertight installation.

- No need to cut the Starlink connectors for installation.

- Marine sealant is not required.

- Paint finishes complies with our unique 4-step marine paint system

- Constructed from the best marine-grade aluminium.

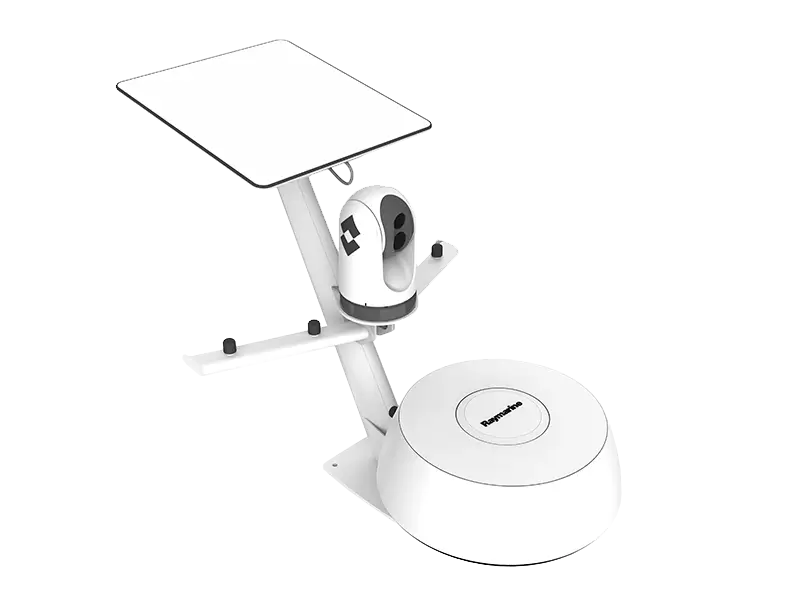

SC-SL-01

Starlink Flat High-Performance Aluminum Wedge

APT-150-SL-01

Starlink Aluminium PowerTower

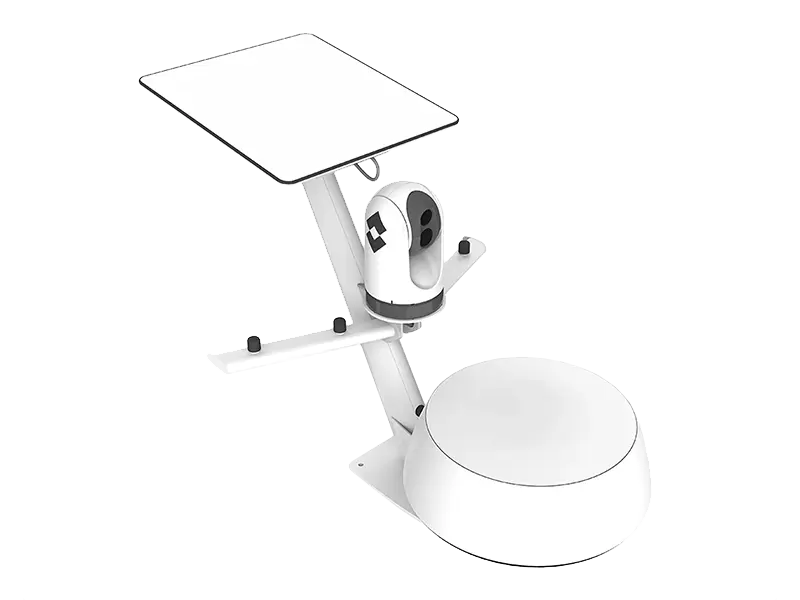

PTM-R1-SL

Starlink Tapered Mast

PTM-R2-SL

Starlink Tapered Mast

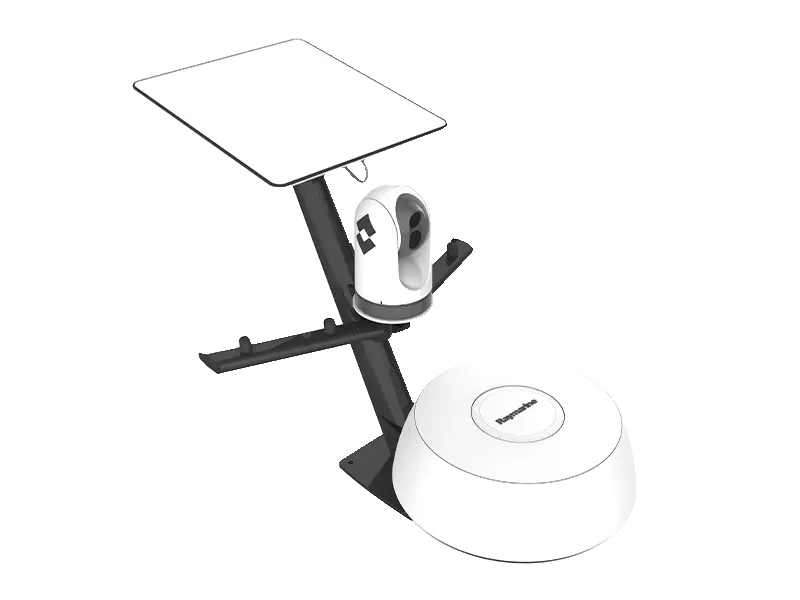

SC-SL-01-BLK

Starlink Flat High-Performance Aluminum Wedge

APT-150-SL-01-BLK

Starlink Aluminium PowerTower

PTM-R1-SL-BLK

Starlink Tapered Mast

2 mins

2 mins Scanstrut Named BLA Supplier of the...

Scanstrut Named BLA Supplier of the Year for 2025

Read more 3 mins

3 mins How to Install A Scanstrut Starlink...

For the best-fitting, purposely designed, and engineered option, here is our tried and tested... Read more

3 mins

3 mins The Top Van Design Considerations...

3 mins

3 mins Key Trends Shaping 2025

2025 has brought together several key trends across industries,... Read more

3 mins

3 mins In conversation with Teulu Tribe

We catch-up with TeuluTribe, aka, Becka and Zach, to hear their intro to sailing and... Read more

7 mins

7 mins In conversation with Viggo Boats

In this interview we speak with Douglas Matton, Production & Brand Manager at

3 mins

3 mins The ultimate Vanlife Game-Changer

3 mins

3 mins 4 trends we saw at boot Düsseldorf

Design

Innovation

Partner

Sustainable

Quality